Plate Heat Exchangers: A Game-Changer in HVAC and Cooling Systems

Heat exchangers play a crucial role in a wide range of industries. They are used for cooling, heating, and energy recovery in systems, including HVAC, power generation, manufacturing, and more. Heat exchangers come in different types, including shell and tube, finned tube, and plate heat exchangers (PHex). Among these, PHex has gained significant popularity in recent years, thanks to its unique design, energy efficiency, and low maintenance.

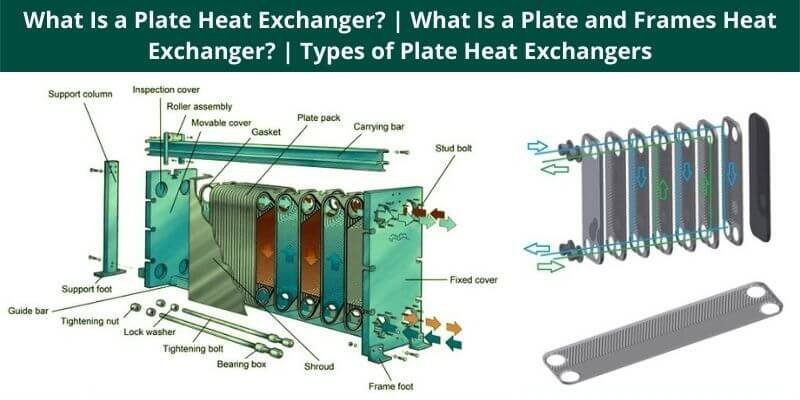

PHex is a compact, thin, and lightweight heat exchanger that uses a series of plates to transfer heat from one fluid to another. The plates are made of metal, such as stainless steel, titanium, or nickel, and are arranged in a parallel pattern. The fluids flow in alternate channels and counter-currently, maximizing the heat transfer efficiency. The result is a highly efficient and effective heat transfer with minimal pressure drop, which translates into lower energy consumption, reduced operating costs, and increased productivity.

PHex technology has revolutionized the HVAC and cooling industry, providing a sustainable solution for temperature control and energy efficiency. PHex can be used in a variety of applications, such as air conditioning, refrigeration, heat recovery, and process cooling. In air conditioning and refrigeration, PHex enhances the cooling capacity and reduces the compressor load, resulting in lower energy consumption and reduced carbon footprint. In heat recovery, PHex captures waste heat and transfers it to other processes or spaces, reducing the need for additional heating sources.

PHex also offers several advantages over traditional heat exchangers. For starters, PHex takes up less space than shell and tube exchangers, which makes it ideal for industrial applications where space is limited. PHex is also easier to clean and maintain, thanks to its removable plates that can be cleaned and inspected separately. This reduces downtime and maintenance costs, enhancing the overall system reliability and availability.

PHex technology has continued to evolve, with new advancements being made to improve performance, efficiency, and sustainability. For example, some PHex models are designed with microchannel plates that increase the heat transfer surface area and reduce the refrigerant charge, resulting in even higher energy savings. Other PHex models are coated with nanomaterials that enhance their heat transfer performance and durability, making them suitable for harsh environments.

In conclusion, PHex is a game-changer in HVAC and cooling systems, providing an efficient and sustainable solution for temperature control and energy savings. With its unique design, energy efficiency, and low maintenance, PHex has become a preferred choice for industries looking to reduce their carbon footprint, enhance productivity, and lower operating costs. As PHex technology continues to advance, we can expect more innovative solutions to emerge, paving the way for a more sustainable future.